E-Consult International

World-class electromechanical engineering

E-Consult offers specialized electromechanics technology and reliability engineering services, aiding in the optimization and realization of electronics hardware from concept to production.

Claus Würtz Nielsen

Technical experience

With more than 35 years of experience, contributing to design and manufacturing of millions of end-user electronic devices, Claus is a leader in his field.

His vast experience has been obtained via employment at several companies in many different engineering job positions such as, Development-, Research-, Production-, Quality-, Failure Analysis-, and Technology-Engineer, as well as project-, group-, department- and business-manager.This combined with his experience from technical and managerial positions within segments as Consumer-, Industrial-, Space- and Medical-Electronics, has given Claus a solid base to give professional consultancy support to companies who wish to be best-in-class in designing and manufacturing of electronics devices.

E-Consult International mainly focus on four different service categories;1) DfX, Reliability and Total Cost optimisation of the physical PCB hardware design and material/technology-selection for your existing electronics.2) Supporting hardware teams to focus on DfX in the hardware creation process of new products from concept to volume production.3) Miniaturization and Modularization of electronics.4) Technology training via Workshops/Seminars.

E-Consult International, Client references:

Claus has been full time employee in 8 companies from 1981 to 2010

and successfully been running E-Consult International since 2010 and hereby given professional sparring to several companies in Denmark and rest of Europa, China and USA.

Here is a list of some of the companies Claus has worked for:

What I do

Areas of expertise

Having helped more than 40 industry leaders within Consumer-, Industrial-, Space- and Medico-Electronics with optimizing their hardware has refined my experience in a variety of fields.• My special competencies are in Electronics / ElectroMechanics production technologies, miniaturization, modularization and Hardware technology concept selection for electronics with high requirements to robustness and reliability in harsh environments (vibration, shock, condensation, liquid ingress, corrosive).

I have deep insight into solutions for automated commercial extreme mass production (Mobile phones) as well as for smaller series production of very high-reliability electronics (Space) and super compact electronics (Hearing aids).

• My main focus is on optimization of the physical hardware design and material/technology-selection with respect to DfX, Manufacturability, Manufacturing yield, Total lifetime cost (not just BOM-cost) and Reliability/Robustness in the field.

Examples of services

My customers typically appreciate to have an external sparring partner who, with fresh eyes and profound experience, questions:

• "This is how we usually do it" and

• "We have used this EMS for many years",

... because "new" component and production technologies sometimes requires a replacement of the toolbox, change of technology and possibly also the EMS to one with better technical capability and ability to deliver high quality.

Sometimes engineers are not aware of that older technologies that years ago have been disregarded, has become significantly optimized and therefore relevant again.

I offer to participate as a sparring partner at concept development meetings and milestone reviews from start to product release for manufacturing, to ensure focus on DfM, DfR, DfA, DfT in product creation projects and ensure that material and hardware technology choices are challenged and discussed sufficiently early to achieve the Lowest Total Cost,I do as well offer:

• to assist with miniaturization and / or modularization of electronics

• to support the development / updating of HW production technology roadmaps

• to give support to material / process / technology research

• to find the best suited EMS for PCB assembly and Box Build

Technical Reviews

PCB-layout DfM review

I offer second-opinion reviews on your existing electronics/electromechanics hardware technology and provide insights for an optimized DfX: DfM, DfBA, DfR, DfT .....

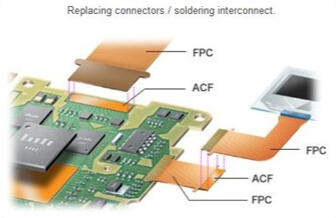

Internal connectivity

review

Concepting and review of Electromechanical interconnect methods.

Proposal of optimized interconnect methods.

Cost reduction

review

Cost reduction review of existing products:

• can the hardware design, material and manufacturing technology selection be optimized?

• Proposal for Next Generation DfX optimization

From concept to production

New device

hardware concepting DfX

I offer to participate as a sparring partner at concept development meetings to ensure that material / hardware technology choices are challenged and discussed.It is as well an option to include me as a part time member of concept and development teams for shorter or longer periods to ensure continous focus and progress on DfM, DfR, DfA, DfBA from concept stage to ramp-up of production, thus achieving Lowest TOTAL Cost.

DESIGN SUPPORT

Design for Excellence

Guidance in PCB and PCBA

Design for:

• Manufacturing

• Assembly and Automation

• Reliability / Robustness

• Test

• Coating / Underfilling

• Lowest Total Cost

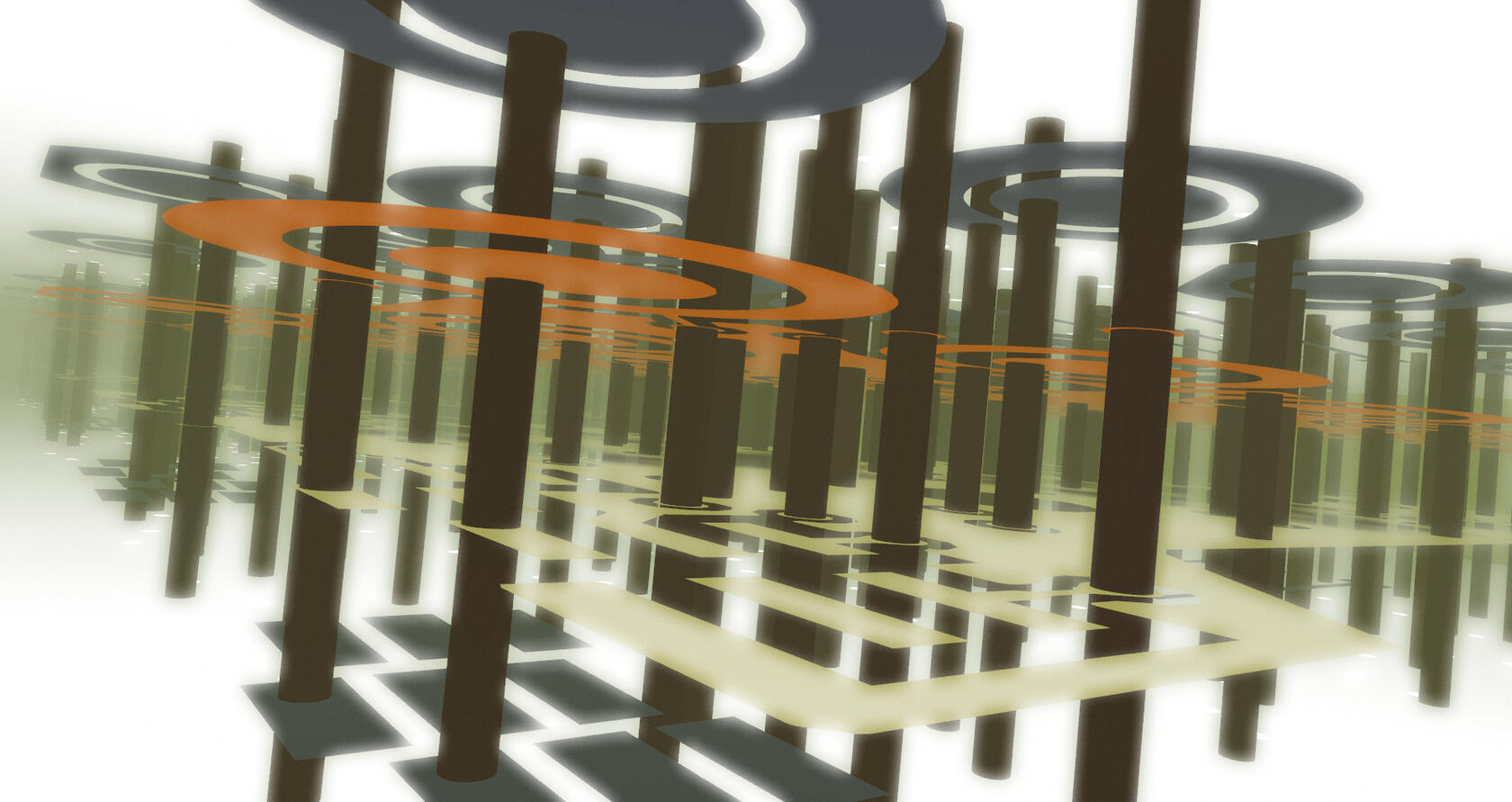

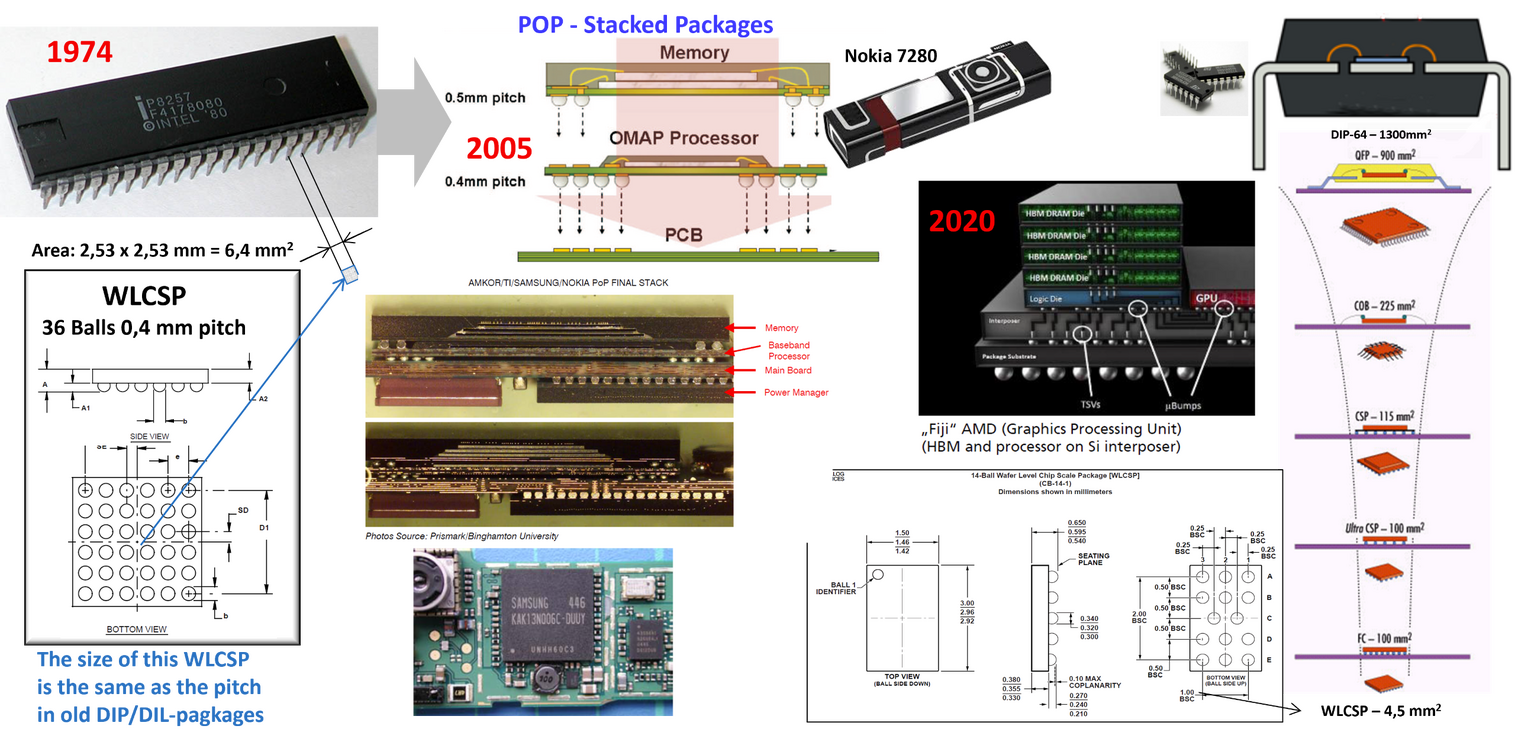

Miniaturization

Are you struggling with space for the electronics but not really familiar with the numerous amazing options for miniaturization using HDI PCB technologies with stacked and staggered MicroVias, then I can guide you to select the most feasible:

• Component technology

• Substrate technology

• Build-up structure

• Footprint design

• Design rules

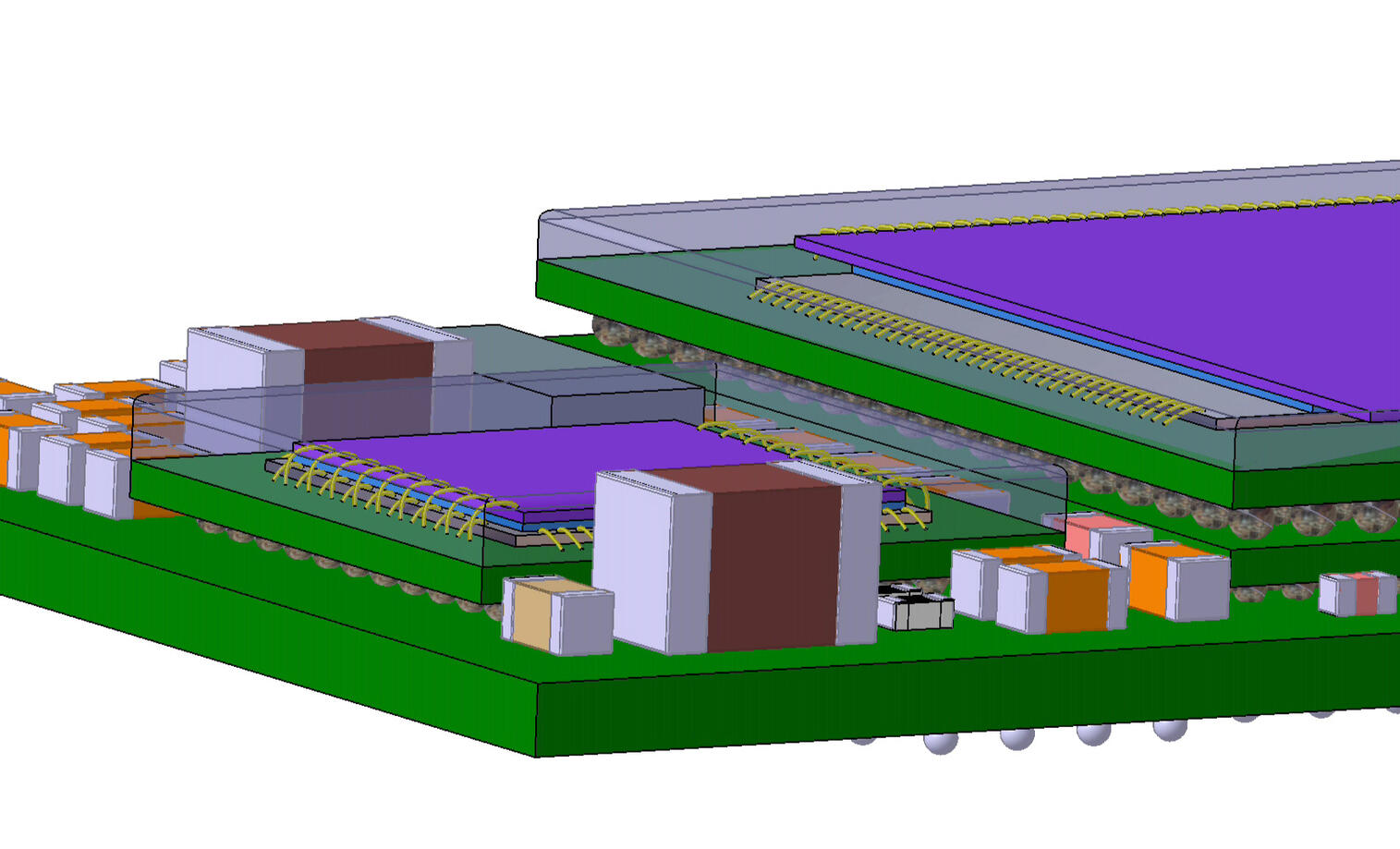

Modularization

Should you consider to go for a HDI PCB module approach?

It of course depends on the actual application, component type mix and complexity.

In many applications a modular approach will enable:

• Faster time to market for new design variants.

• Smaller area Main PCB, and therefore cheaper, because a module typically will give higher packaging density by using finer pitch components and HDI interposers.

• Lower total cost by enabling simpler Main PCB technology with fewer layers.

• Even option for further cost reduction, if the module is used in different products due to higher module volume production.

• Easier and higher yield PCB assembly by use of Known Good modules.I have experience I will be happy to share with you, from design and manufacturing of more than 100 modules and component packages.

PCB AND PCBA MANUFACTURING SUPPORT

EMS Technical Capability assessments

Have you selected a PCB manufacturer and EMS with sufficient technical capability for your specific PCBA design?I have experience from numerous Technical Capability Assessments in Europe and Asia and can therefore analyze your actual needs and support you in the process to select the best suited EMS for your actual needs.

RELIABILITY ASSURANCE

Device reliability

Guidance to:

• Mission Profile creation

• PCB and PCBA Design for Reliability

• Environmental Test requirements

• Device failure Root Cause Analysis guidance

DO YOU NEED INSPIRATION?

Lectures to inspire and upgrade your internal knowledge

Before you can design excellent manufacturable and reliable electronics devices you need to know about:

• traditional and new technology options

• what it takes to manufacture and validate the hardware

• typical root causes to field failures and how to prevent themIf your Hardware creation team need to be updated with a deeper insight in these topics then E-Consult International can create tailor made presentations for a workshop or seminar at your company.

Claus Würtz Nielsen has for more than 3 decades acted as a Technology Scout that each year follow hardware technology events, seminars and conferences to stay updated with newest trends, design and manufacturing methods.Claus has a long track record for giving presentations regarding electronic substrate/manufacturing technologies, failure types, device reliability and robustness to harsh environments, at Technology Seminars and International Microelectronics Conferences (IMAPS, ICEP, SMTA,...) in USA, Japan, China, Germany, The Netherlands, Finland, Norway, Sweden and Denmark.

Claus has also contributed to articles in Electronics magazines and technical publications.

Here is a list of list of public presentations:

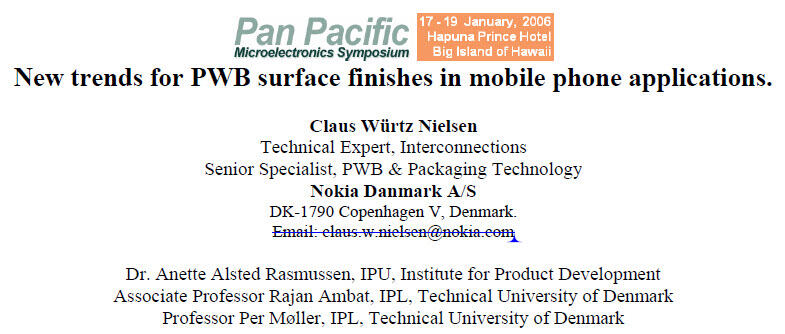

In addition to these, Claus has held numerous customized seminars at the request of private companies.May 2024: SMTA, Electronics in Harsh Environments Conference at DTU, Denmark. Keynote presentation title: Design for high reliability in Harsh Environments.Sep 2022: DfX seminar, Odense, Denmark. In cooperation with Force, GPV, ICAPE. Title: DfX – What, Why and How.June 2017: Asymtek Technology Days, Geldrop, The Netherlands: Title: Coating considerations.June 2015: Asymtek Technology Days, Maastricht, The Netherlands: Title: Why and When is Coat and Underfill needed?Apr 2015: HIN Seminar, Horsens, Denmark: Why and when is Coating and Cleaning needed?Oct 2014: Article in the Danish Electronics News Magazine “Elektronik & Data” October edition: "Coating beskytter elektronikken".Aug 2014: Article in the Danish Electronics News Magazine “Elektronik & Data” August edition: "Dybt i Nokias maskinrum".Jun 2014: PCB Reliability Seminar, Copenhagen, Denmark: How to improve PCB/PCBA design, performance and reliability.Mar 2013: SPM Erfagruppe 20 – DFMA – Design For Manufacturing and Assembly meeting hosted by B&O, Struer, Denmark: From DIL-packages to Embedded Components. The evolution of Component Packaging-, Interconnection- and Substrate-Technologies.Nov 2012: IPU “Corrosion in Electronics” Seminar, Lyngby, Denmark. Title of presentation: Organisation structure impact on reliability problem solving.Dec 2011: Printline Seminar at the Danish Embassy in Oslo Norway.Title of presentation 1: From DIL-Packages to Embedded Components. Title of presentation 2: Interconnect reliability problems and solutions.Nov 2011: Printline Seminar, Odense Denmark. Title of presentation 1: From DIL-Packages to Embedded Components. Title of presentation 2: Interconnect reliability problems and solutions.Jun 2011: Asymtek Technology Days, Heerlen the Netherlands: Title: Micro Coating and Underfill – a must to obtain high reliability of mobile devices.Apr 2006: ICEP Conference, Tokyo Japan: Title: Paradigm shift for PWB surface finishes in mobile phone terminals.Feb 2006: Pan Pacific Electronic Symposium, Hawaii, Title: New trends for PWB surface finishes in mobile phone applications.2004: IMAPS Nordic Conference, Helsingør Denmark: Title: The evolution of surface finishes in mobile phone applications.2003: DAMAG Temadag for printdesignere, Odense Denmark: Title: Kultryk på print.1993: Articles in the Danish Electronics News Magazine “Elektronik & Data”: June edition: Laser trimming Thickfilm Hybrids. October edition: “Chip & Wire” techniques1991: Article in the international magazine “Circuit World” Vol.17, Number 3: Design Guidelines for Polymer Thickfilm Technology.1990: Co-author to: Polymer Thickfilm Technology design guidelines and applications. A result of a Nordic cooperation project (1988-1990) supported by Nordic Fund for Technology and Industrial Development (Nordisk Industrifond). ISBN 82-992193-0-2.1990: Theme days at “Instituttet for Verkstadsteknisk Forskning” (Sweden), and at Elektronik Centralen (Denmark), Title: Polymer Thick Film Connection Techniques.1990: ISHM NORDIC Conference at Ålandsøerne (Finland). Title: PTF, An attractive supplement to traditional Thickfilm and PCB technology.1987: Polymer Circuit and Component Board (PC2B). EC-report ECR-202.1986: ISHM NORDIC Conference in Helsinki, Finland. Title: Results from the PTF Research Project “PC2B” at a-s Elbau, funded by Teknologistyrelsen.1986: Elbau and Radiometer Electronic Theme Day at Hotel Eremitage (Denmark). Title: Undersøgelse af Polymer TykFilm teknologiens muligheder og begrænsninger.1986: EKF-seminar at Hotel Holmenkollen (Norway). Title: Results from the joint Nordic project, PC2B.1985: Elektronik seminar 85, at Bellacenteret (Denmark). Theme: Production techniques in the Electronic Industry. Title: Polymer Circuit and Component Board (PC2B).

LEARN MORE

Technical downloads

If you use ENIG as surface finish on your PCBs and make mobile electronics devices or devices that will be exposed to mechanical impact (drop) or vibration, then the probability for field failures is high.

Read this technical paper to learn how ENIG can promote fatal unavoidable solder joint cracks.

ARTICLE

Dybt i Nokias maskinrum

Portrait article of Claus Würtz Nielsen from Elektronik og Data.

(Text in Danish).

Get in touch

Let's have a chat

E-Consult International ApS, represented by Claus Würtz Nielsen, is situated in Denmark but operating world-wide.

I can meet you online or in the Copenhagen area.

SCAN MY CONTACT INFO